Reverse Engineering of Printed Circuit Boards

Reverse engineering depicts the sequence of operation of reconstructing a complete project database. For successful reconstruction all parts used in the imported board should be defined in EDWinXP part library. From BOM that contains list of all used parts, we can find whether needed parts are already defined and what missing parts have to be added

- Sample Project details

- Reconstruction steps

- Import of ODB++ database

- Netlist Export

- Reconstruction of Library Elements

- Updation of BOM parts

- Import of ODB++ with the script

- Reconstruction of schematics

- Recreate via holes and traces from Gerber import

Sample Project details

Let us reconstruct a project with the following source files:

- Board1-odb++.zip - compressed board database in ODB++ format

- Board1.X01 - Top artwork (Gerber format RS-274-X)

- Board1.X10 - Drill (Gerber format RS-274-X)

- Board1.X11 - Contour (Gerber format RS-274-X)

- Board1.X21 - Bottom artwork (Gerber format RS-274-X)

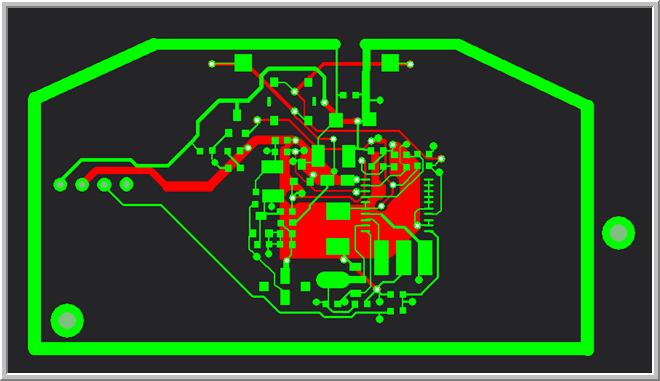

- Board1-picture.jpg = image of the board (unpopulated)

Reconstruction steps

- Import of ODB++ database

- Reconstruction of Library elements

- Import of ODB++ with the script

- Reconstruction of schematics

- Recreate via holes and traces from Gerber import

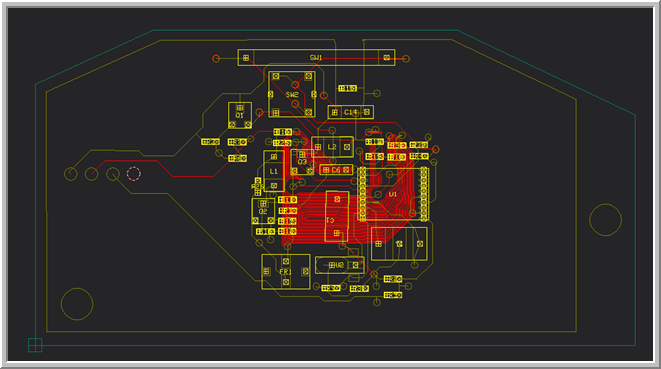

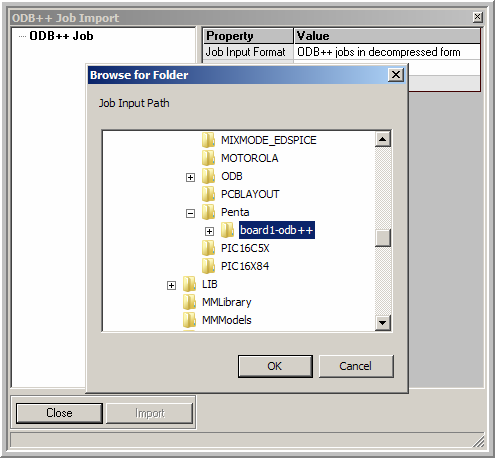

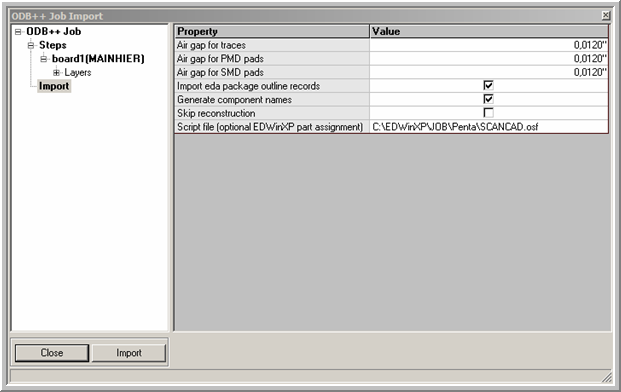

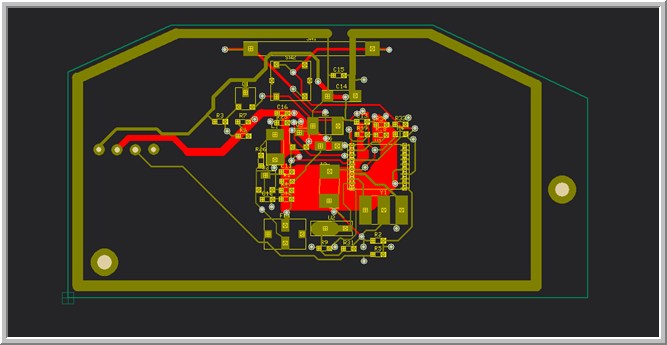

Import of ODB++ database

- Import of ODB++ database

Import of each ODB++ job steps consists of three automatically following phases. Three phases are as follows.

The program finds out the components used on the board and footprints and silkscreen of the required (traces and via holes)

packages during PCB layout import. The result is as follows:

Netlist Export

Exports the net list from the project in order to obtain a template for BOM. During ODB++ import, EDWinXP creates dummy parts that are named as packages. For full part description we need schematic symbol of part (for schematic view) and the package (PCB layout view).The Net list obtained is as follows:

(PATH,Board1 - ODB++ Import(MAINHIER)

(COMPONENTS

C1,1_SMD2_2

C6,1_SMD2_6

C10,1_SMD2_7

C11,1_SMD2_7

C12,1_SMD2_7

C13,1_SMD2_7

C14,1_SMD2_5

C15,1_SMD2_7

C16,1_SMD2_7

R1,1_SMD2_7

R2,1_SMD2_7

R3,1_SMD2_7

R4,1_SMD2_7

R5,1_SMD2_7

R6,1_SMD2_7

R7,1_SMD2_7

R9,1_SMD2_7

R17,1_SMD2_7

R18,1_SMD2_7

R19,1_SMD2_7

R25,1_SMD2_7

R26,1_SMD2_7

R31,1_SMD2_7

R33,1_SMD2_7

R34,1_SMD2_7

Q1,1_SMD3_2

Q2,1_SMD3_3

Q3,1_SMD3_3

L1,1_SMD2_4

L2,1_SMD2_4

U1,1_SMD20_1

U2,1_SMD2_3

FR1,1_SMD4_1

Y1,1_SMD3_1

SW1,1_SMD2_1

SW2,1_SMD6_1

)

(VALUES

C15,NONE

R2,NONE

Q2,NONE

Q3,NONE

Q1,NONE

C6,NONE

C14,NONE

L1,NONE

L2,NONE

U1,NONE

U2,NONE

FR1,NONE

C1,NONE

Y1,NONE

SW1,NONE

C13,NONE

R33,NONE

R34,NONE

R18,NONE

R4,NONE

R1,NONE

C10,NONE

R9,NONE

R5,NONE

R31,NONE

R17,NONE

C11,NONE

R6,NONE

C16,NONE

C12,NONE

R25,NONE

SW2,NONE

R26,NONE

R7,NONE

R3,NONE

R19,NONE

)

(NODES

(9

Y1,3

U1,4

)

(23

R33,2

)

(22

U1,7

R33,1

R34,2

)

(5

U1,1

R9,2

)

(4

U1,20

R2,2

R5,2

)

(21

U1,9

R18,2

)

(3

FR1,4

Q2,2

R26,1

)

(2

U1,2

U2,2

U2,1

R9,1

R31,1

)

(20

L1,2

C11,1

Q2,1

C10,1

)

(19

C6,1

R1,2

)

(15

Q3,2

R18,1

C11,2

R19,2

)

(18

SW1,2

U1,17

R4,2

SW2,3

)

(13

FR1,2

C1,1

Y1,2

U1,18

U1,16

U1,15

U1,14

U1,13

U1,12

U1,11

U1,10

Q3,3

C6,2

U1,19

C16,2

C12,2

R2,1

R1,1

R31,2

R17,2

R7,2

R19,1

C13,2

R34,1

)

(17

C1,2

U1,6

U1,5

Q1,3

R4,1

)

(12

Q3,1

Q1,1

C14,2

C14,1

L2,2

L2,1

C15,2

C15,1

R3,1

C13,1

)

($NONE$

)

(27

U1,8

)

(11

FR1,3

)

(10

FR1,1

)

(32

SW2,2

)

(31

SW2,5

)

(30

SW2,1

)

(29

SW2,4

)

(7

C12,1

Q2,3

C10,2

R17,1

)

(16

R25,2

)

(26

L1,1

C16,1

R25,1

R26,2

)

(25

R6,2

R7,1

)

(24

Q1,2

R6,1

R3,2

)

(6

R5,1

)

(28

SW1,1

SW2,6

)

(8

Y1,1

U1,3

)

(1

)

(33

)

)

(BOARDDATUM,I

0,1376,0,2022

(BOARDVERTEX X,Y,ID

0,0000,0,0000,1

0,0000,1,2400,1

0,5600,1,4950,1

2,0000,1,4950,1

2,8450,1,0950,1

2,8450,0,0000,1

0,0000,0,0000,0

)

)

(COMPPOSITIONS,I

C15,T,1,1.4518,1.2201,2,1.5090,1.2194

R2,T,1,1.6678,0.3153,2,1.7250,0.3146

Q2,T,1,1.0802,0.6723,3,1.1176,0.5926

Q3,T,1,1.2654,0.9069,3,1.3028,0.8272

Q1,T,1,0.9702,1.1278,3,1.0084,1.0469

C6,T,1,1.3801,0.8329,2,1.4729,0.8336

C14,T,1,1.4193,1.1059,2,1.5719,1.1097

L1,T,1,1.1320,0.8952,2,1.1318,0.7578

L2,T,1,1.3398,0.9426,2,1.4772,0.9424

U1,T,1,1.5529,0.6014,20,1.8418,0.6014

U2,T,1,1.4067,0.3815,2,1.5181,0.3815

FR1,T,1,1.0940,0.3503,4,1.1884,0.3014

C1,T,1,1.4284,0.5325,2,1.4310,0.6931

Y1,T,1,1.6269,0.4824,3,1.8243,0.4824

SW1,T,1,0.9986,1.3659,2,1.6661,1.3671

C13,T,1,1.5796,0.9673,2,1.6368,0.9666

R33,T,1,1.7896,0.9519,2,1.8468,0.9512

R34,T,1,1.6858,0.9499,2,1.7430,0.9492

R18,T,1,1.6844,0.8942,2,1.7416,0.8935

R4,T,1,1.7906,0.8994,2,1.8478,0.8987

R1,T,1,1.1690,0.6398,2,1.2262,0.6391

C10,T,1,1.0627,0.5409,2,1.1199,0.5402

R9,T,1,1.3731,0.2723,2,1.4303,0.2716

R5,T,1,1.6678,0.2394,2,1.7250,0.2387

R31,T,1,1.5069,0.2703,2,1.5641,0.2696

R17,T,1,1.1659,0.5903,2,1.2231,0.5896

C11,T,1,1.1669,0.6912,2,1.2241,0.6905

R6,T,1,0.9306,0.8879,2,0.9878,0.8872

C16,T,1,1.1438,1.0136,2,1.2010,1.0129

C12,T,1,1.1664,0.5419,2,1.2236,0.5412

R25,T,1,1.1419,0.9609,2,1.1991,0.9602

SW2,T,1,1.1398,1.1031,6,1.2950,1.1050

R26,T,1,1.0544,0.7248,2,1.0551,0.7820

R7,T,1,0.9283,0.9662,2,0.9855,0.9655

R3,T,1,0.8026,0.9668,2,0.8598,0.9661

R19,T,1,1.5809,0.8974,2,1.6381,0.8967

)

),Board1 -ODB++ Import

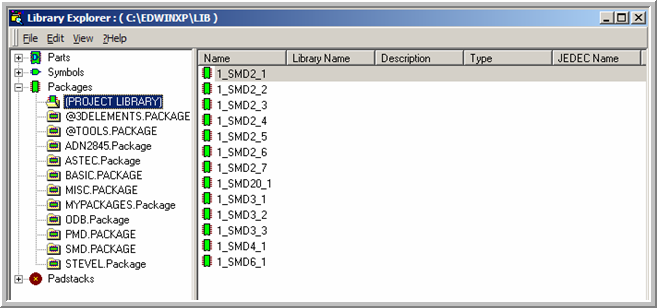

Reconstruction of Library Elements

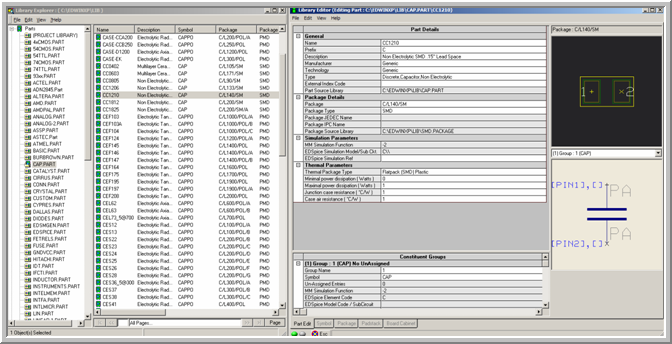

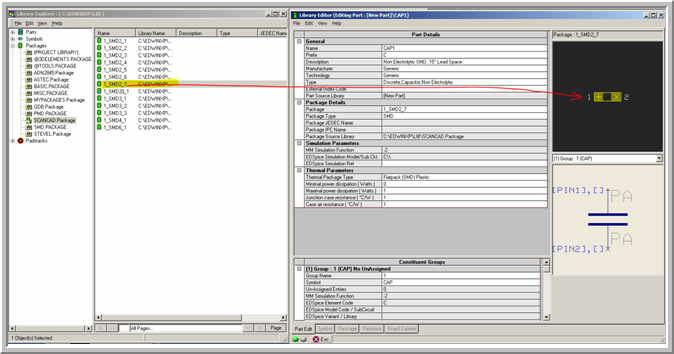

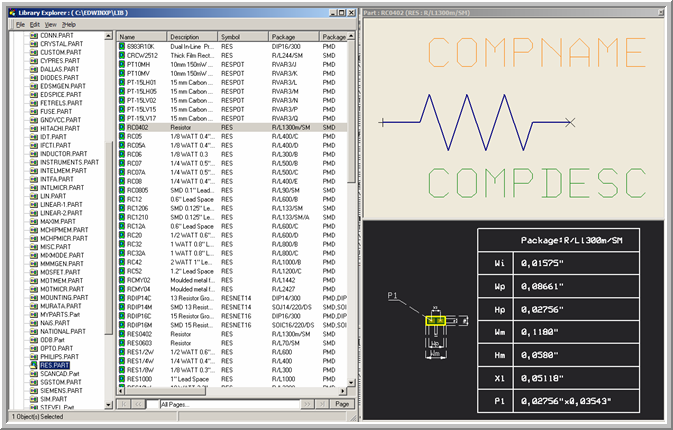

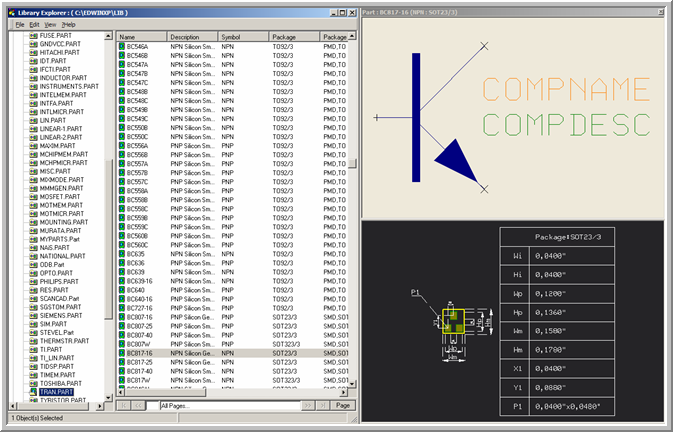

- Import packages in recreated parts and add existing schematic symbols from EDWinXP libraries to part descriptions.

- Reconstruct parts for components on the board using Library Explorer and Library Editor.

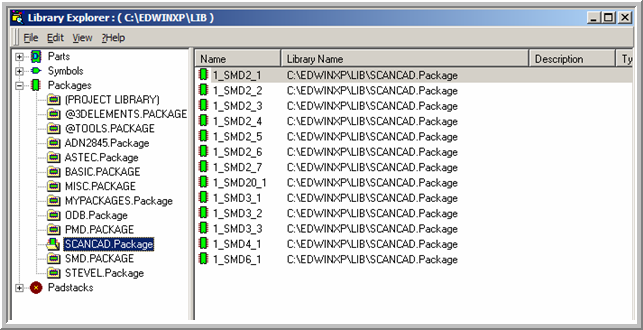

- Extract all packages from the project library and store them in a newly created private library SCANCAD.PACKAGE.

Invoking Library Explorer:

From EDWinXP Main: System -> Library -> Explorer

From Library Explorer: File -> New -> Package Library And using Copy and Paste copy all

imported packages to the newly created private package library SCANCAD.package.

Create empty private libraries for part descriptions – SCANCAD.Part and schematic symbols – SCANCAD.Symbol.

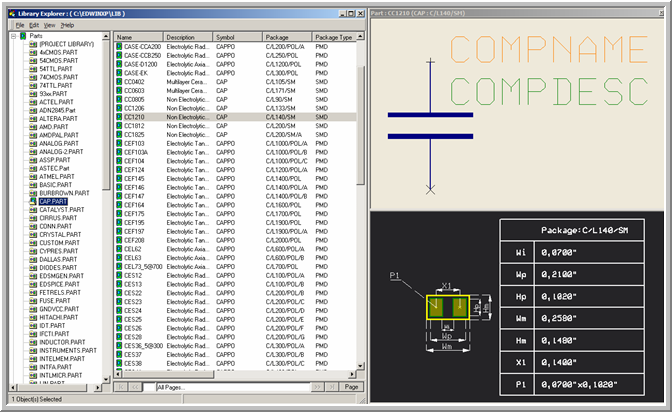

Assume components with C and R name prefixes respectively capacitors and resistors

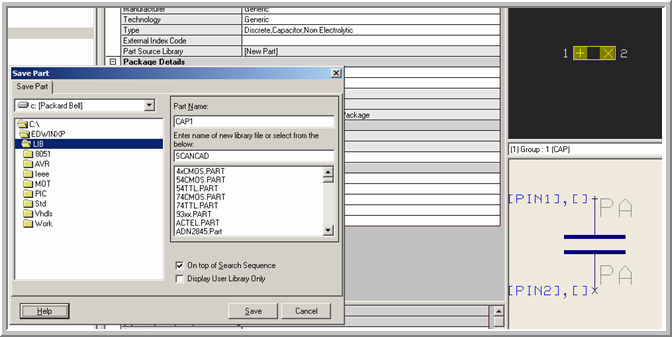

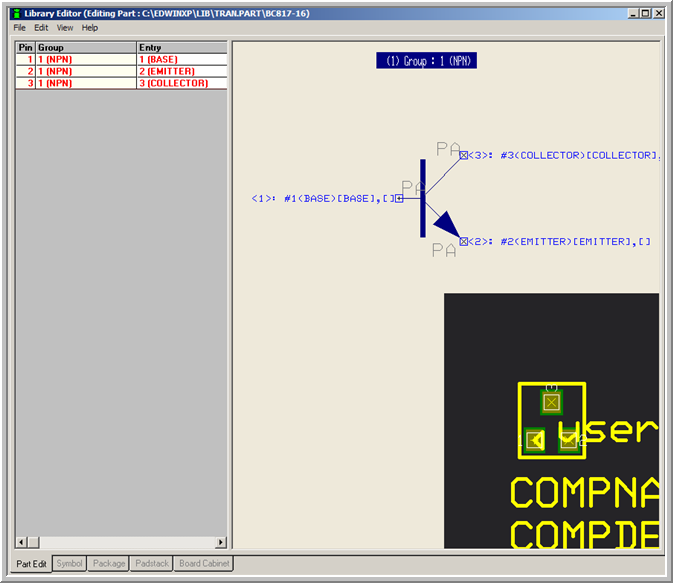

Use existing part as template and just replace referenced package:

For example –select part CC1210 as template and open Library Editor

Replace current package with suitable package from SCANCAD.Package library:

And save the updated part description in SCANCAD.PART library

Create remaining parts for the project.

Change pin assignments for transistors because pin numbers used in EDWinXP differs from those in imported packages:

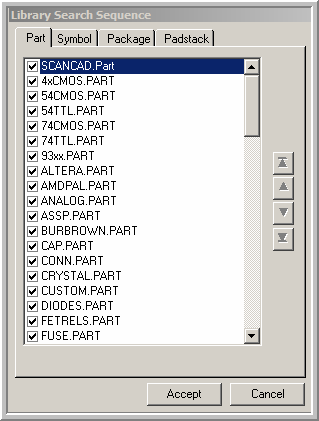

To use private libraries for this project put on top of the search sequence to ensure that when library

elements will be searched for, they will be found first in those libraries and not in system libraries.

(Use dialog invoked from Library Explorer by: View -- >Search Sequence):

Updation of BOM parts

PATH,Board1 - ODB++(MAINHIER)

(COMPONENTS

C1,CAP2

C6,CAP3

C10,CAP1

C11,CAP1

C12,CAP1

C13,CAP1

C14,CAP4

C15,CAP1

C16,CAP1

R1,RESISTOR

R2,RESISTOR

R3,RESISTOR

R4,RESISTOR

R5,RESISTOR

R6,RESISTOR

R7,RESISTOR

R9,RESISTOR

R17,RESISTOR

R18,RESISTOR

R19,RESISTOR

R25,RESISTOR

R26,RESISTOR

R31,RESISTOR

R33,RESISTOR

R34,RESISTOR

Q1,TRANSISTOR1

Q2,TRANSISTOR2

Q3,TRANSISTOR2

L1,INDUCTOR

L2,INDUCTOR

U1,CODEC

U2,SWITCH

FR1,RECTIFIER

Y1,TRIAC

SW1,POT

SW2,VOLREG

)

Import of ODB++ with the script

Import ODB++ with a script assigning library parts to the imported components. Since all recreated parts have references both to PCB packages and corresponding schematic symbols, this import produces complete,editable EDWinXP project. Using script is optional.

(

CAP1(C10,C11,C12,C13,C15,C16)

CAP2(C1)

CAP3(C6)

CAP4(C14)

RESISTOR,(R1,R2,R3,R4,R5,R6,R7,R9,R17,R18,R19,R25,R26,R31,R33,R34)

TRANSISTOR1(Q1)

TRANSISTOR2(Q2,Q3)

INDUCTOR(L1, L2)

CODEC(U1)

SWITCH(U2)

RECTIFIER(FR1)

TRIAC(Y1)

POT(SW1)

VOLREG(SW2)

)

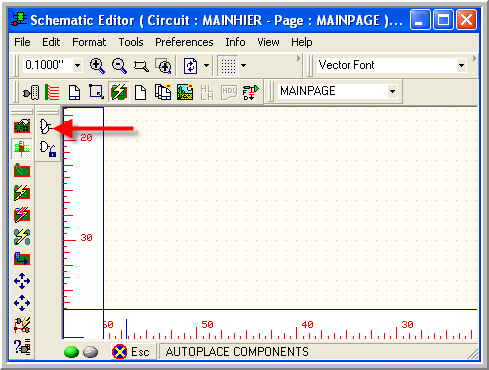

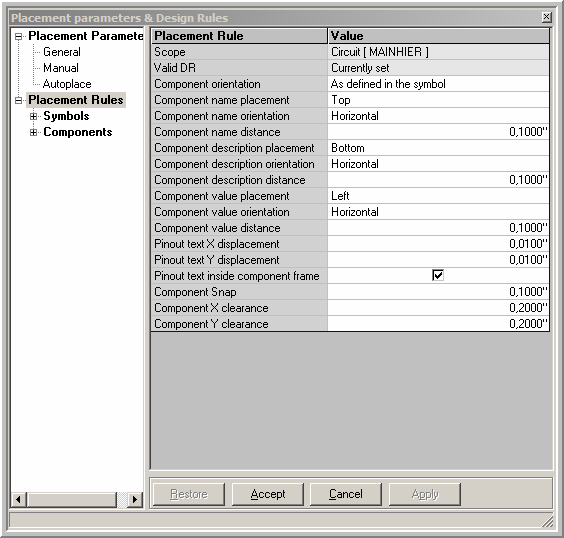

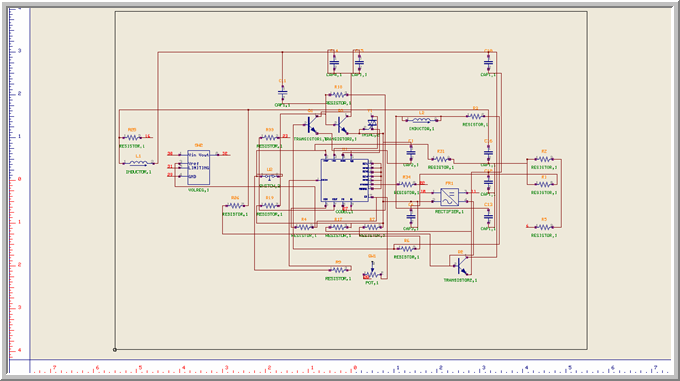

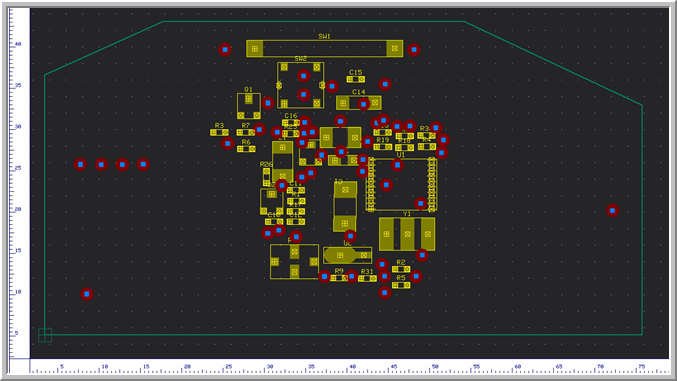

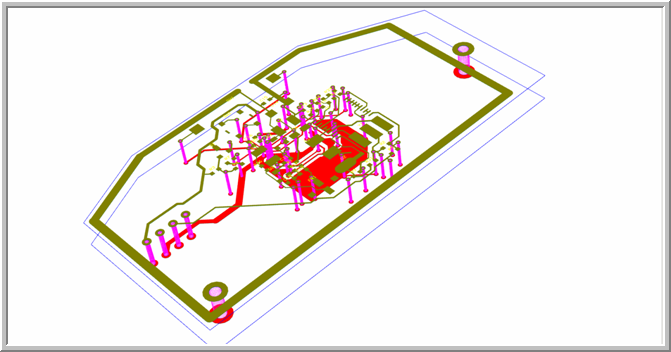

Reconstruction of schematics

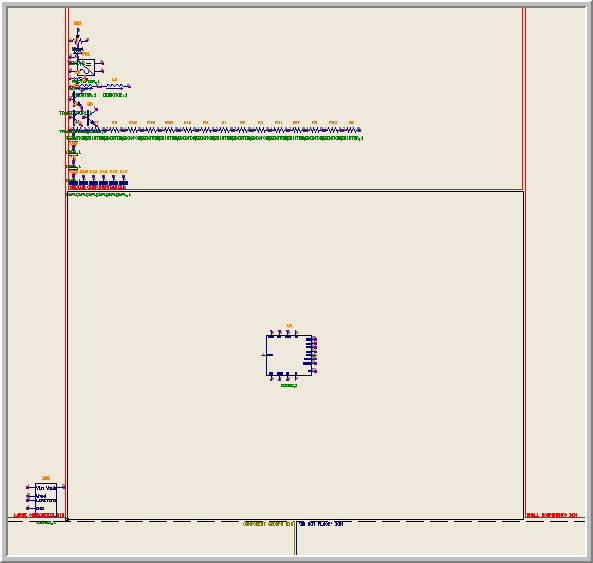

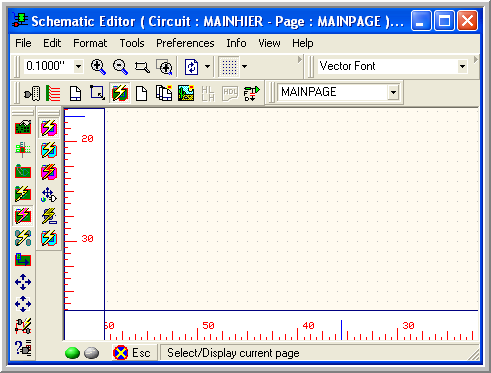

After import, reconstructed schematic components are placed on top of each other at the center of main page. To make a readable

schematic use auto-placer and auto-router from Schematics Editor. These routines have many features which enable fine tuning of results.

Before components are placed they have to be removed from the page to locations outside that we call BINS.

This function produces following results

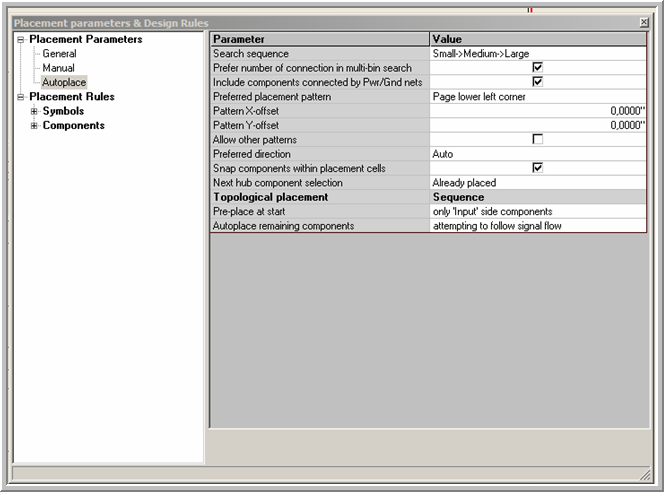

Now set up placement rules

And subsequently set up placement parameters:

Before placement can start, at least one “strategic” component has to be placed manually on the page at desired position.

We call such component as “hub” component because remaining components will be moved from bins and placed in relation to the hub:

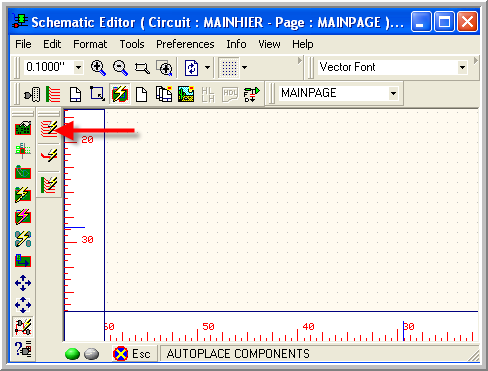

Placement is invoked by selecting tool Autoplace all components with option Autoplace starting from selected hub component and

by clicking on component at the center of the board.

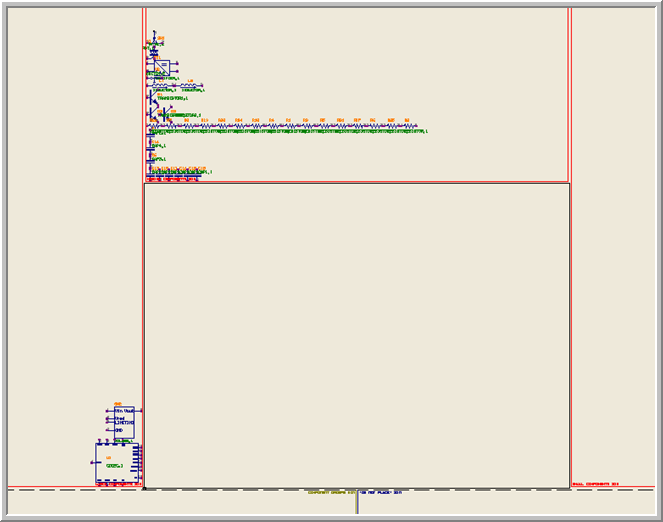

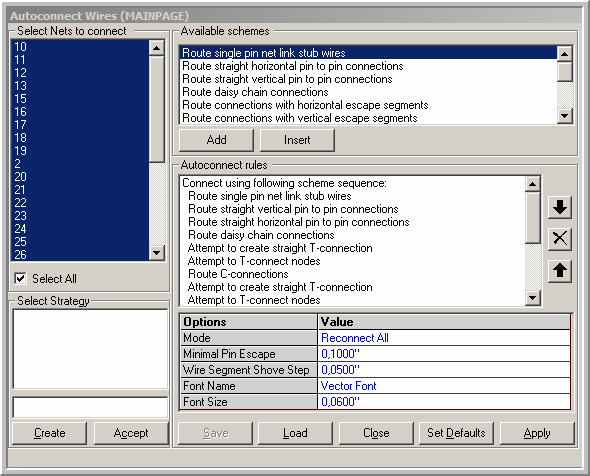

Next step after placement would be routing of wires. In the same menu, select function

Reroute connections and click option Autoconnect wires.

This shows the result of auto-placement and auto-routing:

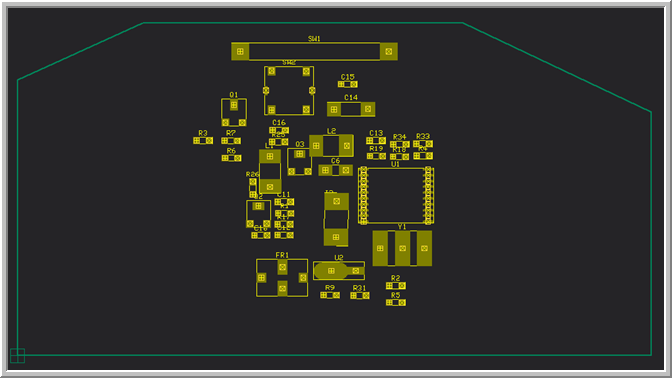

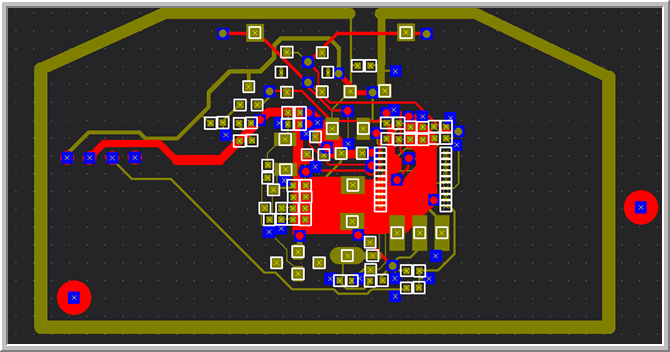

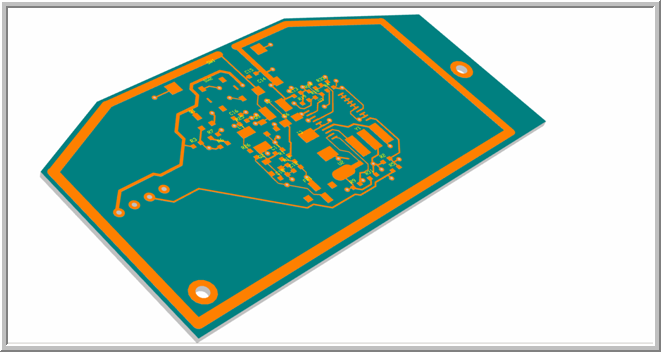

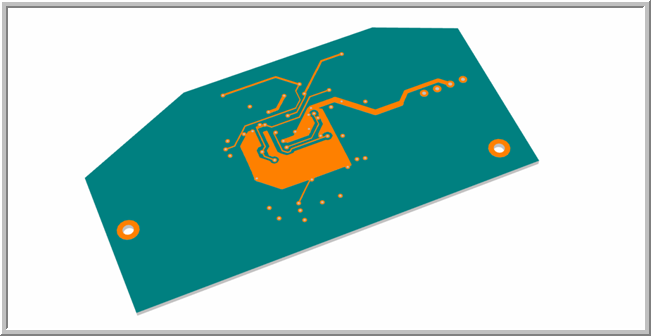

Recreate via holes and traces from Gerber import

Remove all traces and other copper imported from ODB++ leaving only components:

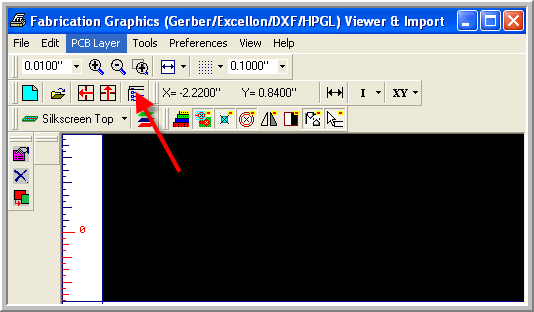

Using Gerber Viewer import artworks for top and bottom layers:

From drill file import holes – though some are missing – probably because on the picture they are filled with solder:

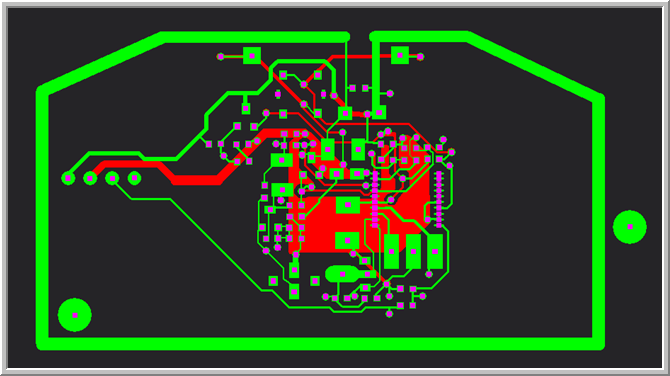

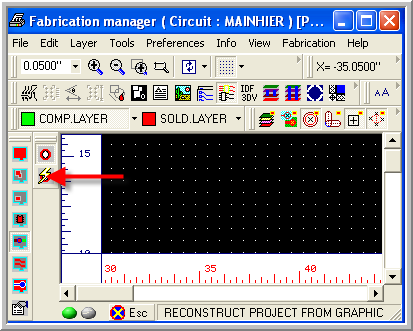

Gerber Viewer allows passing imported graphics to EDWinXP. Fabrication Manager

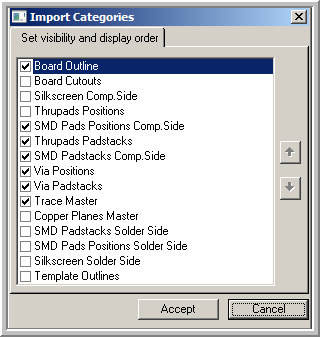

In this module we have a suite of tools for editing imported graphics and preparing them for PCB reconstruction. Imported graphics are

categorized. This is necessary since Gerber data are ambiguous. For example a line may be a trace segment but may also be a SMD pad.

Import process tries to categorize data as much as it can. For example graphics created with flashed apertures (D03*) are assumed to be pads.

Nevertheless some editing and manual categorization of data is in most cases necessary:

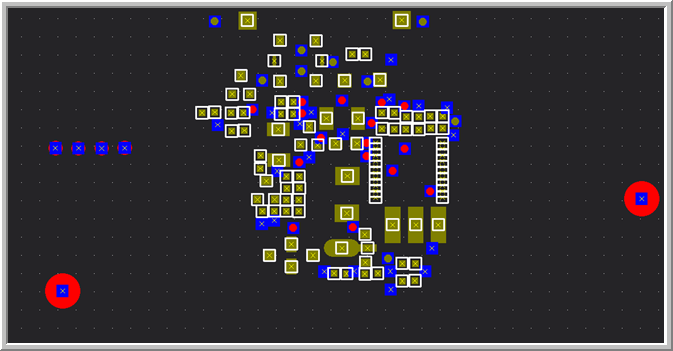

For reconstruction of vias use category Via positions as a template. Since drill file was incomplete (missing holes)

some of via pad positions were categorized as SMD pad positions. Using category to category transfer functions of Graphics

Import Editor in Fabrication Manager create a template for all vias in Via Positions category.

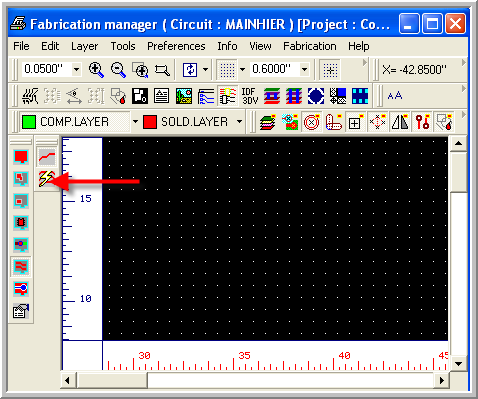

Next Reconstruct from Graphics in Fabrication Manager and reconstruct vias using automatic function.

Vias have to be reconstructed before traces.

Next reconstruct traces. This is also an automatic function in Reconstruct from graphics toolbar.

Adjust pad sizes and hole diameters for 3 different via pad stacks (in Layout Editor)to get a reconstructed = reverse engineered board:

Read More:

Introduction to Reverse Engineering

Reverse Engineering